Scenarios Towards a Sustainable Production Development System

- Nicol Jeyacheya

- Jan 14, 2024

- 21 min read

Authors: ALLEGRA ARDIZZONE, JAKOB PETRI, LAWRENCE JONGI, SANDEEP RAJU, VARVARA VASDEKI

1. Introduction

For the past decades, according to the Paris Agreement [1], sustainability is a key element for the future of manufacturing and the focus of governments and industry has rapidly shifted towards more sustainable production strategies. The researchers of this paper aim to draw an outlook onto a more sustainable production system, including social, economic, and environmental aspects, while answering questions on how to develop and align the current system with the Sustainable Development Goals [2]. Furthermore, this paper aims to conceptualize and define selected steps towards the vague term of “responsible production”, by giving a literature-based overview on the following strategic developments and trends in industry from a predominantly managerial point of view.

The Lean concept, as a widespread framework in the industry for efficiency improvement and waste reduction, is firstly analysed. The paper provides a brief theoretical background and an evolution-concept for Lean implementation and maturity stages, as well as challenges and limitations, and approaches to overcome them. Practical industrial examples are discussed, based on WAGO, a manufacturing company for electronic and automation components.

Next, the concept of Environmental Production Management (EPM) is introduced, questioning and analysing the implementation and every-day usage of it. The State-of-the-Art towards EPM is described, relying on the case study of AstraZeneca, a leading company in the pharma industry. Green Performance Mapping is discussed as a tool for identifying potentials to improve production sustainability, focusing on challenges and approaches to overbear those.

Within the next part, driven by current events, such as the COVID-19 crisis and the Ukrainian war, the Management of major disturbances in a production context is addressed and helpful tools are discussed. Contributing to the analysis of the topic, an interview with TE Connectivity, a global manufacturer of connectivity and sensing products, was conducted.

The last paragraph is focused on the Digital Transformation of industries towards a sustainable future system. The effects on digitalization on lean management are discussed with input from TE Connectivity, a global company providing sensor and connectivity solutions. Finally, the positive impact of digitalization to gender equality and diversity is elaborated, supported by an interview with a representative of SCANIA, a leading company in the automotive heavy-duty sector.

2. Lean Production Implementation and Improvement

2.1 Theoretical Framework and State-of-the-Art

Lean manufacturing is a methodology inspired by the Toyota Production System (TPS) in Japan in the 1980s. It focuses on adding value and eliminating waste from an organization, aiming at producing higher quality products in the least time and at the lowest costs. Based on the two pillars of Jidoka and Just-In-Time (JIT), the basic theoretical framework of lean, the Lean House, describes the five steps necessary to implement lean manufacturing:

Identify Customer’s needs and operations strategy

Identify waste in the system.

Recognize and categorize different types of waste (Seven Component Wastes: Transport, Inventory, Motion, Waiting, Overprocessing, Overproduction, and Defects)

Find solutions for the root causes generating the waste

Test solutions before implementing them

Different tools are used for lean purpose, such as Value Stream Mapping, Kaizen, Material Requirement Planning, Kanban, and the 5S [3]. Figure 1 shows each relative function.

2.2 Lean Evolution Framework

As stated from Hines et al. [4], the Lean journey evolved from a “Tool-Based Change” with high variability in the performance, to a “System-Based Change” increasing stability and improvement, and ultimately to a “Cultural-Based Change”, characterized by a consistent and faster improvement. These stages describe how the lean maturity framework has shifted from the use of tools to create stability, such as 5s, Failure Modes and Effects Analysis (FMEA) and Problem Follow Ups (PFUs), followed by a second phase in which such tools were applied in “a context of a coherent strategic roadmap” and finally to the third stage based on a Plan-Do-Check-Act (PDCA) Cycle. The model thinking, shown in Figure 2 and 3, aims at changing the idea of Lean as an operational and tool-based approach, by focusing more on the importance of systems, people, and culture, as well as the sustainability of such change.

2.3 Discussion and Results towards a successful Lean implementation

The implementation of Lean in the production system of companies comes with various obstacles and enormous complexity, resulting in percentages of less than 10% of successful lean implementation projects which lead to significant improvements [5]. This happens mostly due to the “incomplete understanding of the […] concept”, the “use of (the) wrong tool to solve a problem” or “of (a) single tool to solve all problems” [6] and “the lack of attention paid to human resource management”, the organizational culture (OC) and soft practices [7]. Schonberger speaks of a disintegration of Lean manufacturing and Lean management, which means that the cause of “leans downslide (is) owed to the tendency to spend more effort on peripheral pursuits […] and less on actually changing the process for the better” [8]. The complexity of the concept often leads rather to confusion than on customer centric process improvements.

Based on an interview with Michael J. Zemmrich-Coester, Head of Lean Management at WAGO and former Head of Operational Excellence at Siemens Wind Power, a major issue within the implementation of Lean management is a lack of C-suite support and pull as a key element [9]. Furthermore, Lean is less a project with a specific end date but should be seen more as a continuous and ultimately infinite way of acting and thinking. Many companies focus on the use of tools and methodologies but pay too little attention to the corporate culture and the employee training and awareness-creation.

To overcome those critical factors, the implementation of Lean should be done in an integrated way, regarding a top-down long-term strategy and Specific, Measurable, Achievable, Relevant, TimeBound (SMART) annual goals, cascaded down to the shopfloor and a bottom-up understanding, commitment and mindset to continuous improvement and learning culture. According to ZemmrichCoester, Hoshin Kanri should be used as a tool to address and broaden the strategic goals within different hierarchies of a company [9]. Bortolotti describes the following success factors in OC and lean practices, visualized in Figure 4 and underlines the significance of people and culture [7]. It is important to “walk-the-talk” about Lean-related aspects in a company. Knowledge externalization, job-rotation, workshops, trainings, and sense-giving for the employees are viable tools for the implementation of Lean management.

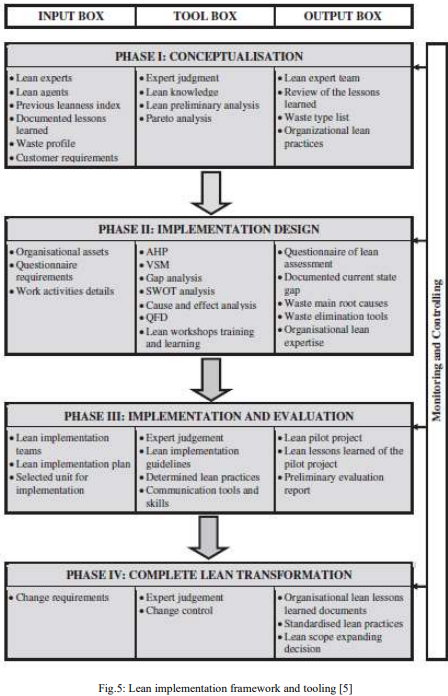

Stable and standardized processes are critical for a successful long-term change process. Tasks should be well-defined and documented to build a solid foundation for optimization efforts. Furthermore, the selection and usage of tools should be well considered, as e.g., JIT do not provide a universal fit to every process. A broad catalogue of tools and methods is needed. In [6], Mostafa provides a framework/phase-model with a toolbox and defines nine critical factors for a successful lean implementation, visible in Figure 5.

According to this standardized implementation flow process, Zemmrich-Coester provides a WAGO company-specific implementation guideline [9]. He clearly states that the timeline is meant as a tool for orientation and must not be seen as a strict framework. The WAGO Lean Implementation Guideline is visible in Figure 6.

To meet the climate goals, based on the Paris Agreement in 2015, and to transform a company’s production system towards higher sustainability, it is necessary to “achieve business growth along with simultaneously reducing the consumption of resources, strive to become leaner in its operations” [10]. This goes hand in hand with the basic beliefs and values of Lean management. Figure 7 connects the theoretical pillows of Lean with the triple bottom line of sustainability. Achieving a higher level of leanness and with so, a higher level of efficiency, can lead to cost savings, material waste reduction and increased job satisfaction and training for employees in accordance with the triple bottom line of sustainability. Zemmrich-Coester stated potential for enhancing a company’s productivity with Lean of 20-25% [9]. He referred to the example of Porsche company’s site in Leipzig, where the implementation of Lean has led, during a period of seven years, to an improvement of their quality from 100 ppm to 0.9 ppm, which ultimately increased the overall value.

3. Environmental Production Management

3.1 State-of-the-Art

Green Performance Mapping (GPM), or Green Kaizen, is a tool of the Green Production System that uses the system transformational (input to output) concept and material flow cost mapping to improve environmental performance, using circular economy and the lean concept [11]. It uses the value-added concept, which will be extended below to metrics associated with energy, water, material, air, and products. This technique requires inputs of shopfloor personnel to transform an organisation to utilise both explicit and tacit knowledge, through the following processes: 1. Identify environmental aspects from the eight quadrants and the root cause; 2. Determine the effect of the problem and prioritise problems; 3. Develop an action plan for the solutions; 4. Implement solutions and develop a consistent Kaizen Kata on solutions, investigate challenges and opportunities from other solutions, but do not challenge the system unless it is stable; 5. Follow up solutions using monitoring and evaluation tools, document findings from costs, environmental improvements. Since the identification of priorities is done by the shopfloor personnel, it improves fundamental mindset change which stimulates and utilises personnel creativity. Circular strategies like converting waste output to resource input (circulation by looping) or substitution (replacement of technology, material, and energy input) can be employed in the material quadrant, which contradicts with lean linearity [12]. The tool is great for visualisation. However, it is not critical on non-value adding but necessary materials e.g., machine oils and grease which have an impact on the environment. There is a need to quantify and audit the level of environmental footprint of the process e.g., quantifying the environmental footprint of the input material, energy, water, and equipment. That is, how much energy is wasted by a kilogram of input material waste, water, and what are the implications of defective products to the environmental footprint calculated from the entire value chain perspective, of not only the materials but of the machines in terms of tear and wear and obsolete value. The tool does not cite the possibility of circularity in residual energy recovery from the system. It only shows energy into the system without any residual energy recovery, which means that it requires great creativity and innovation to utilise it to improve circularity in process material (non-value adding), e.g., gloves, which can be used multiple times through washing [13]. The authors looked into the company AstraZeneca as a case study, a leading company in the pharma industry and a great example of a firm practising GPM.

AstraZeneca (AZ) strategic values prioritise growth through innovative strategy. interconnecting business growth, the needs of society and the limitations of the planet. AZ has operated in nine African countries in screening 29 million blood pressure communal people and has successfully managed to establish partnerships with the ministerial departments in those countries. They have a Carbon Neutrality project of planting 50 million trees by 2025 (but the expected amount of carbon sequestration from the project is missing) and it is critical to note that the United Nations is now focusing on adaptation measures. Therefore, the tree planting activity done by AZ should not only focus on landscape restoration but agroforestry and conserving biodiversity, so that society can derive many benefits from the activity and people’s livelihoods will be improved from ecosystem services. According to AZ Sustainability Report 2021 [14], its sector is heavily regulated, meaning there is little room to practise circularity. Therefore, the way they are practising circularity is through cross-sectoral collaboration and venturing into the entire supply chain network according to SMI: The Circular Bioeconomy Alliance [15]. This might be fruitless as some tier suppliers are difficult to engage, as AZ can only access 75% of suppliers in their network.

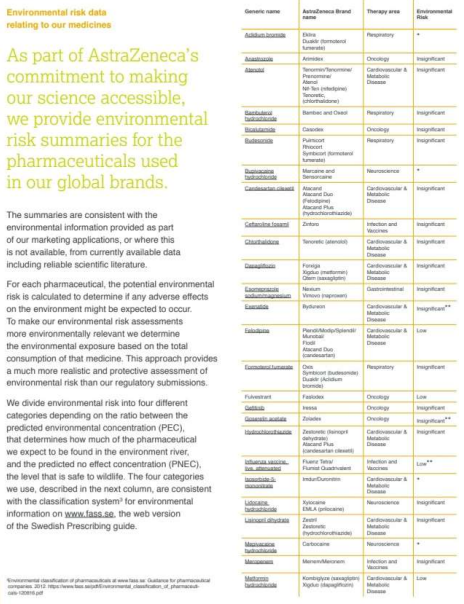

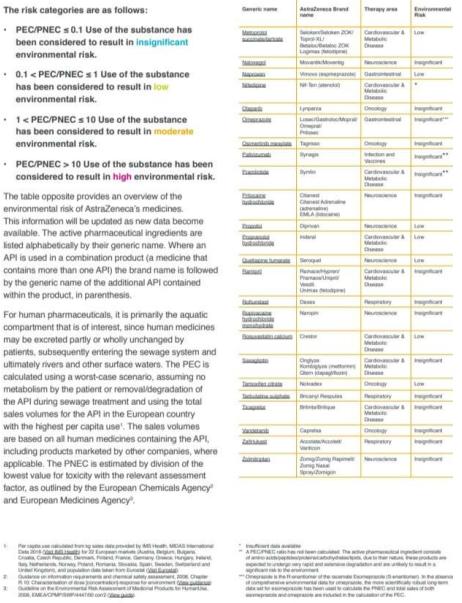

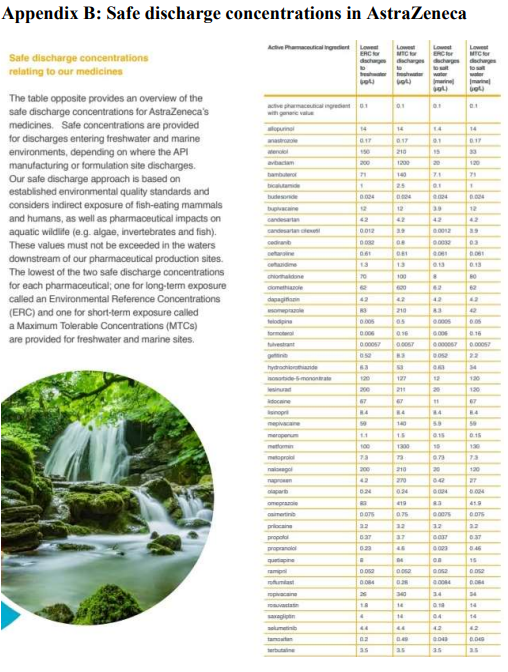

According to the AZ Sustainability Data Summary of 2021 [16], they will have 100% electric vehicles on the road by 2025. If Scope 3 of this initiative is missing, the project might be adding more environmental footprint than it is preventing. There is an imminent need for AZ to quantify Scope 3 emissions, regarding not only the supply network of pharmaceutical ingredients but also the equipment and machinery they use in value creation. Although, in the sustainability report, the amount of water usage is clear, the firm does not show indicators such as water turbidity, temperature, pH and colour per year, which is critical in water stewardship, even though AZ is claiming [17] that Active Pharmaceutical Ingredients (API) are not harmful to the environment [Appendix 1 and 2 of the Pharmaceuticals in the Environment Report].

AZ imports 100% of electricity as of 2021 and has managed to reduce energy consumption by 9% from 2015 baseline, it is equally important to quantify the amount of energy lost during importation transmission of power. Supply chain network engagement as of 2021 is at 75%, therefore, although Sustainability Data Summary of 2021 [16] is clearly showing Scope 3, it means there is a -25% degree of confidence with the data which will cumulatively add with data inaccuracy of the existing data. Gender balance has been on a sturdy rise on all company levels. In 2021, AZ recorded two fatalities which is not a usual incident, hence, it is important for the firm to clearly state the causes of these fatalities.

3.2 Discussion on Challenges integrating Green & Lean Production Systems

Although green practices are being used in lean practices, they are not being helpful in addressing the industrial ecological effects of production enterprises, because lean is concerned about organisational operation, but green is concerned about both intra-organizational and the influence of the organisation on the ecosystem with regards to environmental footprint. Some waste is not found in the eight types, which are inherent in the product, process, machinery and material. For example, a plastic bottle production line is calibrated to produce a bottle with 3mm thick wall, which means every time a bottle is produced there is extra waste of material, energy, and everything in the entire value chain.

Green practices view the environment as a live stakeholder (customer) but lean practices view the customer as the consumer, hence that difference in views creates a divergent view on value, e.g., the company can be practising lean using hazardous or non-renewable resources that does not make it green. Each company has different lean and green metrics, resulting in some KPIs contradicting each other; for example, more frequent deliveries due to reduction of inventory will increase logistics carbon footprint. However, a company which focuses on environmental sustainability might identify, venture, and capitalise on emerging opportunities in this space e.g., a steel making company might recover residual heat and sell steam, this will eliminate the cost that comes with installation and management of a cooling tower.

It is difficult to capture physical waste in relation to financial performance on the shopfloor. This is predominantly because the personnel handling materials are not aware of their cost and other penaltyrelated costs due to environmental emissions, which can be abated by costing, accounting, and training of value adding, non-value adding and non-value adding but necessary materials, waste (water and materials) and activities. Most companies are getting their environmental footprint from a theoretical framework or previous related research. However, environmental sustainability demands real time empirical data (direct measurement), which means the company should invest in environmental monitoring and evaluating equipment to measure their footprint and set real targets. Lean and Green Production Systems can only be integrated, if the definition of customer in Lean is changed, so that it is inclusive of the environment as a live stakeholder and active customer. This requires innovative, revolutionary change management, including values, enabling technologies, energy, time, finance, personnel, materials, products, cultures, transformational processes and goals, to reduce the negative environmental impacts of transformational processes.

4. Managing Disturbances in Production Operations

4.1 State-of-the-Art

Supply chain systems are dynamic, non-linear, and virtually chaotic in today's ever-changing client demand patterns [18]. To sustain better margins, resource planning, production planning, and industrial control systems must be able to respond swiftly to unanticipated disruptions in any value chain activity. To maintain or improve system performance, scheduling plans, material availability, logistics, and labour planning must rapidly adjust to these changes [19]. A manufacturing disturbance is a sudden interruption in output. For example, to manufacture a car, you would need ~10K parts, and even if one component is missing, the whole production line is disturbed [20].

In industrial production environments on the shop floor, two types of categories might influence scheduling and planning: internal and external [16], [20]. Computational failures, operator errors, machine breakdowns, quality and production rate variability in machine performance, labour unavailability, demand change, new quality issues, layout re-configuration, and delays in material and information transfer throughout the production are the most common internal interruptions [18], [19].

Other interruptions include fluctuations in production rate, which result in lower productivity and greater waste, bottlenecks, which cause major drops in production rates, and staff and pallet distribution along the line [18], [19]. Other external circumstances, such as the COVID-19 epidemic, the Evergreen ship trapped in the Suez Canal, chip shortages, metal shortages, sanctions and so on, are unpredictable [20], [21]. These issues affect both buying and selling of materials and products.

4.2 Discussion on Industry Challenges and Solutions

The already expensive energy drains margins, and additional disturbances cause inflation in production costs. Manufacturing companies can absorb a certain amount of these 'additional' costs, but the rest are trickled down to customers, who in most cases, refuse to pay additional costs due to a competitive market. Most methods for coping with disruptions are essentially reactive, with remedial steps performed only when a disruption occurs. Certain types of unexpected occurrences may be predicted using Artificial Intelligence or Machine Learning algorithms in an agile and adaptive system, transforming these events into “anticipated” disruptions that can assist in improved supply chain driver planning [19], [20].

For an adaptive system to function, the disturbance management mechanism must respond to each situation and assess the data to decide if the event was unexpected or the consequence of an unlearned pattern. Adaptive Holonic Control Architecture for Distributed Manufacturing Systems (ADACOR) is a solution to predict future disturbances based on the frequency analysis of each type of disturbance [22], visible in Figure 9. This kind of predictive mechanism enables us to recognize patterns of disturbance occurrences, allowing us to plan the events of future disruptions. With increased observation time, it is feasible to get new insights in the stochastic industrial environment, learn and find information, and certain disruptions may become predictable phenomena [18], [19]. Techniques like Discrete-Event Simulation (DES) – shown in Figure 8 – are an imitation of a proposed or real-world process. A DES model enables the study of experiments on a complex system in a virtual world. The advantage of using DES is the ability to analyse dynamic interactions between systems. Also, the time frame can be expanded or compressed to study the effects of bottlenecks [23], [24].

4.3 Discussion on Utilizing Analytics to Manage Production Disruptions

It is difficult to assess the impact of disturbances on production performance indicators. Each scenario needs to be analysed to understand how they propagate in the system and their associated consequences. The level of impact caused depends on the type of disturbance and the physical and temporal conditions, and each disturbance type leads to a specific repercussion in the system. For example, the production system is less affected by adding a new resource than by the occurrence of failure. In another situation, disturbance on a bottleneck (critical) path has a much higher impact than disruption in a process with alternative paths.

Using analytics, the output of the system can be optimized to deliver higher results without much investment. When relevant data is collected and analysed for different alternatives, many possibilities can be made that are beneficial for the manufacturing process by mitigating disturbances, sometimes even eliminating disturbances. With visibility from the ADACOR model and knowledge about unforeseen scenarios from DES, many scenarios can be modelled, and business models can be prepared to tackle these events. Simple solutions like Overall Equipment Efficiency (OEE) may not be dynamic in nature, but they are effective, adoptable, and easy to understand.

The data allows for the investigation of numerous changes in manufacturing systems. The automatic data logging system made it possible to conduct elaborate tests. Each real-life alteration could be further explored in the simulation model as well. The conversion of data from the automatic data collection system to the simulation model is an area that could be further improved. In the study, a time-consuming translation of data had to be carried out. This issue may be solved by script routines and standard interfaces.

5. Digitalization and Management

5.1 State-of-the-Art

Digitalization in industrial organizations is founded on two distinguished but interconnected pillars: technical and social systems. Technological advancements in industry are focused on digital information, computing, communicational and connectivity technologies. A recent literature review states that the most discussed technologies for digitalization of industrial organizations, particularly in supply chain and logistics operations, are Internet of Things (IoT), Integrated Systems and Big Data & Analytics [25]. Future scenarios towards a more digitalized industry focus on the usage of Blockchain, Cyber-Physical Systems and Digital Twins [26].

On the other hand, digital transformation implies that social systems including people, objectives, procedures, and structures, play a crucial role in change management and implementation. The main enablers of digital transformation seem to be leadership, structure, and culture [27]. Business leaders should focus on developing innovative practices, competence, and strategies to handle these new technologies and enable the creation and capture of maximum value from digital transformation [28]. However, proper change management is required to overcome structural and cultural challenges such as structural rigidity, traditional hierarchies, silos, organizational size, and old-fashioned leadership [29].

5.2 Discussion on Digitalization and Lean Manufacturing

From the state-of-the-art in digitalization, it is evident that despite the rapid technological advancements appearing in the past decade, digital transformation requires careful design and implementation so as not to interfere with established practices. One of the areas directly correlating with digital transformation is lean thinking and practices.

Technology is an essential tool for lean advancement. Applying Information and Communications Technology (ICT) into lean production systems can improve performance and efficiency [30]. An example described by the Director for Digital Transformation at TE Connectivity, Vinay Satrasala, is the process of waste reduction from different production phases. “Let’s say we identified a process with 20-30% scrap. Our highly skilled team of manufacturing engineers need to know why this is happening to come up with an appropriate solution. So, we equip them with the right digital tools to better visualize and understand the situation to identify where the waste is coming from” [20].

Vice versa, lean is an enabler of digital transformation since lean philosophy provides the digitalization process with focus, direction, and tools. Lean thinking involves creating strategic planning according to the lean principles. The same approach can be used to define clear digitalization objectives and form digital strategies by using lean tools to identify, analyse, and evaluate prospects and risks. For instance, through VSM, production phases in need of reducing inefficiency gaps can be selected to implement innovative technologies [31].

However, digitalization of outdated or disorganized processes can place severe limitations on the development of a firm’s digital competitive advantages. If a manufacturing firm does not have lean thinking and implementations in its core philosophy, the leap to a digital tomorrow imposes the risk of digitizing the wasteful activities of today resulting in digital waste [32]. Besides that, digitalization might interfere with established practices that are already working in an efficient way. Digital tools tend to be rigid leading to methods becoming inconsistent to fit the structure of the tools, instead of tools being tailored to the pre-existing methods which ultimately adds extra complexity and violates basic lean design principles [32].

Scepticism regarding the impact of digitalization also originates from the employees, according to Vinay at TE Connectivity. “When people are used to processes for years, trying to bring in new technologies might feel like a threat, since their practices are already tested and work. There might be losses of primitive knowledge on systems and tools if digitization is not done properly”. It all comes down to proper change management.

5.3 Discussion on Digitalization and Gender Equality - Diversity

Digital transformation requires competent leadership to be properly diffused across various levels of an organisation. One of the traits characterising good leadership should be the ability to eliminate biases concerning demographics such as gender, race, and age. Management strategies regarding digital transformation should focus on closing gender and generational gaps in different teams while aligning that with building digital competencies across business units, leading to more socially sustainable businesses.

The most essential advantage of the digital era is the ability to collect data across countries and business units. Managers can overview, monitor, and understand the current situation and build more informed and evidence-driven strategies. A practical example of such practice is Scania where a team of experts, focused on gender equality and diversity, is building a global HR data system for easy access and comparison of facts and figures worldwide. As Irene Molendjjk, project manager, stated: “Now all business units have their own data/data-analysts, so it is tough to compare. With the new system we will make big steps in analytics and comparisons on a global level.” Currently they use digital tools on a local level to spot gender imbalances and discrimination, including recruitment checklists, team assessment tools, and diversity & inclusion (D&I) surveys. An interesting example is the Skill Capture project, Scania’s framework for developing D&I practices and implementing them in everyday work. All entities must deliver key gender figures to identify areas with gender imbalances and key processes in need of change. Here digitalization and HR analytics is key [34].

Digital transformation practices in organisations can have a broader impact touching upon gender equality within households. With recent regulations in many countries and firms, especially after the pandemic, both parents have the option to hybrid or remote working, enabling them to fairly divide their time between work and childcare or household chores. According to Irene’s experience, this is currently happening at Scania worldwide with a noticeable gender balance on remotely working employees. Unfortunately, exact figures are not yet available but will be within the scope of their global HR data system of 2023.

6. Conclusion

Lean philosophy emphasises on eliminating everything that does not add value to the value chain. Although it is a customer-centric philosophy [35], it has been critiqued as a hindrance to radical innovation because of its incremental Kaizen KATA approach [36]. Firstly, for lean practices to be able to integrate all the thematic areas, it is critical to redefine its definition of customer; consumers, eco-systems, digital and social systems, as well as operations which are being modelled by disturbances. The aim is to create unison of shared mental state in decision making including all customers in the system. As value flows, it is important to have a multi-lance approach, evaluating the values and objectives of all stakeholders; global, regional, national, corporate, and personnel to increase the complexity of value creation.

The authors have identified the system customers and stakeholders, and redefined value, to have a win-win situation for all customers and stakeholders. Production Systems need resources; personnel, materials, energy, finance, time, partners, equipment, ICT infrastructure, and market are some of the basics. For example, an effective Production System needs key people with the right skill sets and fundamental mindset as well as diversity in gender, race, and religion to add value. Redefining the customer means environmental production operations like circularity and remanufacturing will be in unison with lean. For instance, substituting a material that is not environmentally friendly in the waste hierarchy becomes a lean operation. Reliability, quality, and responsiveness gives the firm effectiveness against disturbances which cannot be avoided, by leveraging lean and digitalization through applying predictive and prescriptive machine learning. For example, using remaining useful life predictive machine learning eliminates downtime causing improvements in machine availability and firm reliability to fulfil orders. Eliminating waste using Green Performance Mapping reduces rework (hence reducing operation costs) and in turn increases quality resulting in customer satisfaction, results in firm reliability and sustainability. Demand forecasting and aggregate planning algorithms, utilising customer order decoupling point, makes the firm supply orders in the right quantity to the right customer at the right time as pulled by customers, eliminating stock-in-cash to achieve JIT, hence increasing responsiveness to disturbances. However, it is key to note that technology can go as far without practical inference of qualified operations managers who have performance improvement competencies. Therefore, having exposed how digital space is a customer to lean practices, it is critical that ICT infrastructures acquire and facilitate accurate, effective, and timeous data and information for efficient and effective decision making.

Figures

References

[1] UNFCCC. (2015). The Paris Agreement. Paris Climate Change Conference. Retrieved from https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:22016A1019(01)

[2] Sustainable Development Goals. (2015, September). Retrieved from United Nations | Department of Economic and Social Affairs | Sustainable Development https://sdgs.un.org/goals

[3] Gupta, S., & Kumar, J. S. (2013). A literature review of lean manufacturing. International Journal of Management Science and Engineering Management, 241-249. doi:10.1080/17509653.2013.825074

[4] Hines, P., Taylor, D., & Walsh, A. (2020). The Lean journey: have we got it wrong? Total Quality Management and Business Excellence, 389-406. doi:10.1080/14783363.2018.1429258

[5] Baker, P. (2002). Why is lean so far off? Works Management, 26-29. https://www.researchgate.net/publication/306168378_Why_is_lean_so_far_off

[6] Mostafa, S., Dumrak, J., & Soltan, H. (2013). A framework for lean manufacturing implementation. Production & Manufacturing Research, 44-64.

[7] Bortolotti, T., Boscari, S., & Danese, P. (2015). Successful lean implementation: Organizational culture and soft lean practices. International Journal of Production Economics, 182-201. doi:https://doi.org/10.1016/j.ijpe.2014.10.013

[8] Schonberger, R. (2019). The disintegration of lean manufacturing and lean management. Business Horizons, 359-371. doi:https://doi.org/10.1016/j.bushor.2019.01.004

[9] Zemmrich-Coester, M. (2022, 11 17). Lean Management in Industry today. (J. Petri, Interviewer)

[10] Thomas, A., Francis, M., John, E., & Davies, A. (2012). Identifying the characteristics for achieving sustainable manufacturing companies. Journal of Manufacturing Technology Management, 426-440. doi:https://doi.org/10.1108/17410381211230376

[11] Bellgran Monica, M. W. (2012). Green Production System. FFI Sustainable Manufacturing Program.

[12] Kurdve, M., & Bellgran, M. (2021). Green lean operationalisation of the circular economy concept on production shop floor level. Journal of Cleaner Production, 123-223. doi:https://doi.org/10.1016/j.jclepro.2020.123223

[13] Muñoz-Villamizar, A., Santos, J., Garcia-Sabater, J., Lleo, A., & Grau, P. (2019). Green value stream mapping approach to improving productivity and environmental performance. International Journal of Productivity and Performance Management, 608-625. doi:10.1108/IJPPM-06-2018-0216

[14] Ageborg, K. (2021). Sustainability Report. Stockholm: AstraZeneca. Retrieved from https://www.astrazeneca.com/content/dam/az/Sustainability/2022/pdf/Sustainability_Report_ 2021.pdf

[15] What is a Circular Bioeconomy? (2022). Retrieved from Circular Bio-Economy Alliance: https://circularbioeconomyalliance.org/about/what-is-a-circular-bioeconomy/

[16] AstraZeneca. (2021). Sustainability Data Summary. AstraZeneca. Retrieved from https://www.astrazeneca.com/content/dam/az/Sustainability/2022/pdf/Sustainability_Data_Su mmary_2021.pdf

[17] AstraZeneca. (2022). Pharmaceuticals in the Environment. Retrieved from AstraZeneca | Sustainability: https://www.astrazeneca.com/sustainability/environmentalprotection/pharmaceuticals-in-the-environment.html

[18] Leitão, P., & Restivo, F. (2004). Predictive disturbance management in manufacturing control systems. Retrieved from https://bibliotecadigital.ipb.pt/bitstream/10198/1546/1/2004- IMSForum.pdf

[19] Bokrantz, J., S. A., Ylipää, T., & Stahre, J. (2016). Handling of production disturbances in the manufacturing industry. Journal of Manufacturing Technology Management, 1054-1075. doi:10.1108/JMTM-02-2016-0023

[20] Satrasala, V. (2022, 11 25). Disruptions and Digitalization Management. (S. Raju, & V. Vasdeki, Interviewers)

[21] Kumar, A., Luthra, S., Kumar Mangla, S., & Kazançoğlu, Y. (2020). COVID-19 impact on sustainable production and operations management. Sustainable Operations and Computers, 1-7. doi:https://doi.org/10.1016/j.susoc.2020.06.001

[22] Leitão, P., & Restivo, F. (2006). ADACOR: A holonic architecture for agile and adaptive manufacturing control. Computers in Industry, 121-130. doi:https://doi.org/10.1016/j.compind.2005.05.005

[23] Ingemansson, A. (2004). On Reduction of Production Disturbances in Manufacturing Systems Based on Discrete-Event Simulation. Lund Institute of Technology: Department of Electrical and Information Technology.

[24] Yesilgul, M., & Nasser, F. (2013). Discrete event modelling and Simulation of an Assembly Line at GKN Driveline Köping AB. Eskilstuna, Sweden: Mälardalen University, School of Innovation, Design and Engineering.

[25] Baber, S., & Leo, P. (2022). Industrial Revolution 4.0 and Supply Chain Digitalization. South Asian Journal of Social Review, 21-41.

[26] Lu, Y., Liu, C., I-Kai Wang, K., Huang, H., & Xu, X. (2020). Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robotics and Computer-Integrated Manufacturing. doi:https://doi.org/10.1016/j.rcim.2019.101837

[27] Imran, F., Shahzad, K., Butt, A., & Kantola, J. (2021). Digital Transformation of Industrial Organizations: Toward an Integrated Framework. Change Management, 451-479. doi: https://doi.org/10.1080/14697017.2021.1929406

[28] Carlsson, L., Olsson, A. K., & Eriksson, K. (2022). Taking Responsibility for Industrial Digitalization: Navigating Organizational Challenges. The Role of Digitalization and Industry 4.0 Technologies for Product and Production Development in the Manufacturing Industry. doi:https://doi.org/10.3390/su14020866

[29] Imran, F., Shahzad, K., Butt, A., & Kantola, J. (2022). Structural Challenges to Adopt Digital Transformation in Industrial Organizations: A Multiple Case Study. Human Factors in Management and Leadership, 47-52.

[30] Dombrowski, U., Richter, T., & Krenkel, P. (2017). Interdependencies of Industrie 4.0 & Lean Production Systems: A Use Cases Analysis. Procedia Manufacturing, 1061-1068. doi:https://doi.org/10.1016/j.promfg.2017.07.217

[31] Romero, D., Flores, M., Herrera, M., & Resendez, H. (2019). Five Management Pillars for Digital Transformation Integrating the Lean Thinking Philosophy. 2019 IEEE International Conference on Engineering, Technology and Innovation, 1-8. doi:10.1109/ICE.2019.8792650

[32] Powell, D., Morgan, R., & Howe, G. (2021). Lean First … then Digitalize: A Standard Approach for Industry 4.0 Implementation in SMEs. Advances in Production Management Systems, 31-39. doi:10.1007/978-3-030-85902-2_4

[33] Stechert, C., & Balzerkiewitz, H.-P. (2020). Digitalization of a Lean Product Development Organization. Procedia CIRP, 764-769. doi:https://doi.org/10.1016/j.procir.2020.02.232

[34] Molendjik, I. (2022, 11 24). How digitalization affects gender equality and diversity. (V. Vasdeki, Interviewer)

[35] Womack, James P. & Jones, Dan. (2003). Lean Thinking. Revised and updated. Free Press. 396 p.

[36] Larsson, L. (2017). Characteristics of Production Innovation. The International Society for Professional Innovation Management. Lulea University of Technology

Appendix A: Environmental risk data in AstraZeneca

Comments